Maschinenfabrik Gustav EIRICH is a manufacturer of industrial mixers, granulators and mills. EIRICH is active worldwide in the ceramic and refractory industry, foundries, concrete and building materials, battery pastes, fertilizers, glass and the processing of ores, filter dust and ashes.

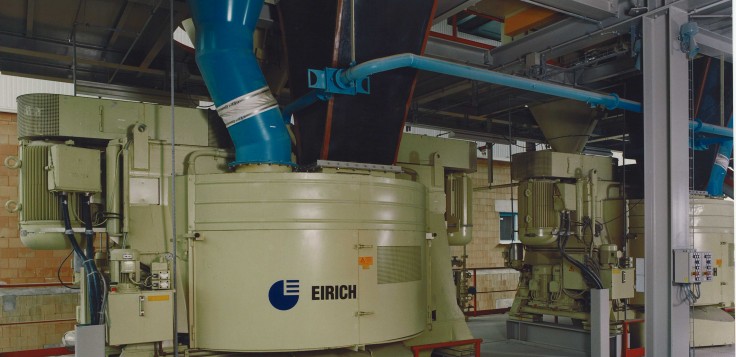

Concrete / Building materials

EIRICH offer globally unique expertise and exceptional synergy potential in the field of raw materials processing for the manufacture of high-grade building materials. Our intensive mixers are delivering a highly reproducible mix which also allows re-mixing of small quantities or homogeneous mixing-in of fibers or pigments. EIRICH intensive mixers are robust and extremely well suited to the special demands arising from the abrasive raw materials which are processed in the building materials industry.

Features:

- Short mixing times

- Optimal homogeneity

- Reproducible result

- Lower fall out rate

- All types and consistencies of concrete can be mixed

- Reduction of cement and pigment quantities

Ceramics

For many decades EIRICH has offered top technologies for the preparation of raw materials and bodies in the ceramic industry, centering on the basic operations of mixing and fine grinding. Many further developments in the field of ceramics and fine ceramics became possible in the first place thanks to innovative solutions by EIRICH.

- raw materials

- mixes

- compounds

- ceramics

- fine ceramics

Glass

The homogeneity of the mixture is the key factor which determines the quality of the glass, and EIRICH intensive mixers produce more homogeneous mixtures in shorter mixing times. The intensive mixers can also handle individual components which sometimes vary in terms of their proportions in the formula, apparent density or specific weight, particle size distribution, grain shape, solubility or wettability, tendency to agglomerate,…

Advantages:

- Shorter mixing times can can raise plant output / increased furnace throughput and quality

- Reduction of waste thanks to the increased homogeneity of each mixture and reliable disintegration of agglomerates

- Savings of melting energy

- Minimum contamination by iron particles due to less wear

- The replacement of simple mixing systems for premix processing optimizes the process of blending in very small component quantities and requires only low investment

- The direct addition of even very small component quantities into an Eirich intensive mixer (used as the main mixer) increases plant flexibility

- Pelletizing of dust, raw materials and mixture reduces demixing problems, the dust burden (insertion area and melting end) and the level of melting energy which is required

Chemical

In the chemical industry , which brings together the varied process technology, the Eirich processing technology is mainly used in:

- Catalyst mass

- Household and toilet soaps

- Detergents and cleaning products

- Building material chemistry products

- Fertiliser and soil products

- Animal Feed

- Herbicide, Pesticide and Insecticide

Also for drying slurry and not only in the context of production but also in the context of environmental protection.

The EVACTHERM (reactor-mixer combined with vacuum technology) technology plays an important role:

- To eliminate undesirable effects in the atmosphere

- To recover solvents

- To remove gas from process material

- By evaporative cooling at low temperatures

- For drying e.g. with superheated vapours

- For pelletising by drying

- For inertisation

- For ecological processes

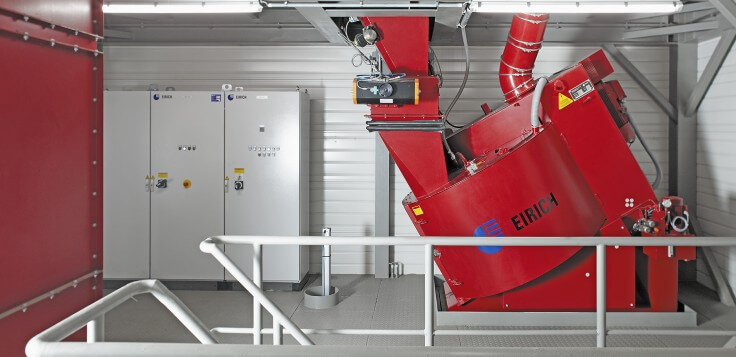

Foundry

EIRICH specializes in systems for preparing bentonite-bonded molding sand, and for many years the company has maintained a close working relationship with foundries, moldmakers and research organizations.

Conventional processing

State-of the art compacting technology for sand molds can make a significant contribution to casting efficiency provided that the molding sand consistently meets stringent quality criteria. The machines and systems of EIRICH for molding sand preperation allow users to meet the essential quality criteria for molding sand:

- Exact compliance with compactibility specifications

- Excellent flowability

- Uniform strength values

- Optimal gas permeability

EIRICH can offer everything from a basic package to the complete solution with all facilities, from the storage of raw materials to the processing of old sand and transfer of mixing plant.

Vacuum processing

- Cooling and mixing in the same machine

- The EIRICH intensive mixer with its high mixing qualities always guarantees the best quality of moulded sand, which is essential for modern foundries. This guarantee is independent of the processing conditions: under atmospheric conditions with a conventional cooling system or when using the unique Evactherm method.

The Evactherm offers the best solution for cases in which:

- Mixing and cooling are necessar

- A high thermal load of moulded sand is present

- The need for moulded sand is >40m³/h

Metallurgy

The use of “intensive mixers” in the metal industry offers a significant advantage to the user. This includes the following processes:

Core applications

- Preparation of pellets and micropellets

- Sinter mix preparation

- Recycling of valuable residues like dusts, ashes, sludges, slurries

- Fine grinding

- Preparation of carbon paste for graphite electrodes, anodes, cathodes

- Coal preparation

Environmental protection

EIRICH supplies technologies for the economical preparation of raw materials, auxiliary materials and residues for recycling and disposal. The product line includes not only machinery and systems but also a full range of services covering everything from consulting to start-up.

- Dusts / filter dusts: The dust is bound through agglomeration or pelletization in order to optimize recycling, handling, transport, storage, depositing in landfills.

- Ashes: The ashes are conditioned through processes of mixing, cooling, reaction, dust binding, degassing and are recycled as a building material or deposited in landfills.

- Slurries / filter cake: Conditioning through mixing/homogenization, drying, granulating for recycling, continued use e.g. in thermal processes, volume and weight reduction or processing into a condition suitable for depositing in a landfill.

- Secondary fuels: Mixing/homogenization under inert gas condition of solvent-containing materials with the help of carrier substances like sawdust.

- Gypsum : Conditioning for reuse in the building materials industry.

Thanks to the EIRICH technology used, it is often possible to do without separate equipment for the treatment of residual materials or for the recycling of valuable resources. Good examples are the Evactherm® and Evacmix ® process developed by EIRICH which have proved particularly successful in applications for processing slurries and lumpy materials.

Refractories

EIRICH intensive mixers guarantee high quality standards even for large production quantities, frequent formula changes and varying consistencies. Throughout the world, companies use EIRICH technology to successfully manufacture refractories to the highest quality standards. Specialist expertise has been gained in the following product areas:

- Molding compounds for all types of bricks; also as hot mixtures

- Casting compounds

- Compounds for refractory lightweight bricks, foaming compounds

- Unshaped products

- Dense vibrating, casting, ramming, spraying compounds and mixtures

- Thermal insulation compounds

- Mortar and putty

- Special materials

- Mixtures and granulates for oxide ceramic and non oxide ceramic materials

- Mixtures for ceramic fiber materials

Fertilizers

EIRICH offers innovative solutions in the field of fertilizers and regards itself as the partner of choice for the fertilizer industry. Regardless of the size of the project, EIRICH can supply everything from stand-alone granulation systems to turn-key fertilizer systems. Thanks to the unique mixing technology it is possible to produce granules with the desired specification that are stable when stored.

Specifications:

- Mixing, granulating and coating in a single machine

- Optimum distribution of trace elements and additives

- Use of secondary raw materials in the form of filter cakes, sludges and nutrient salt solutions

- Environmentally friendly granulating process, no escaping fine dust or aerosol

- Systematic production of long-term fertilizers

Laboratory

Laboratory Mixers of the EL serie: Mixers for research, development and small production

The laboratory mixers of the EL series are available in sizes of 1 to 10 liters. They have all the features of the multifunction EIRICH mixing system and can be used for a great variety of challenging processing applications, such as mixing, granulating, coating, kneading, dispersing, dissolving, defibrating, and many more.

Advantages

- Versatile – Different consistencies can be processed in the mixer, from dry to plastic and pasty.

- Fast and effective – Hiqh mixing qualities are obtained already after short mixing times.

- Scale-up without limit – The linear transfer of the test results to industrial scale is possible.